It may not be rocket science to transfer an image from a computer display to a substrate like a sheet of paper, but it’s close. Digital printing requires an array of disparate technologies that are all specifically designed to work together flawlessly. Complex code converts pixels on a screen into a digital stream that drives the imaging engine in an ink or toner-based device. Electronics, mechanics, optics, chemistry, and more are all employed to physically move the ink or toner from the imaging device to the page and do so in a way that renders a perfect image that will last for years.

Regardless of the type of device, many of the technologies that actually put the image on a page are contained within the machine’s consumables. Thus, the print quality and longevity of the hardcopy from any digital imaging device depends largely on the consumables that are employed. Certain electrophotographic devices are designed to use separate toner cartridges and drums, while others employ a single cartridge that contains a drum. In either instance, it is inside these cartridges that the magic happens and the image is formed and transferred onto the paper. Likewise, some inkjet machines feature permanent print heads that are supplied with inks from external tanks, while others have cartridges with built-in heads that fire the ink droplets. In either case, the ability of any inkjet machine to precisely form and place miniscule picoliters of ink onto a page has a lot to do with what’s inside the cartridges.

Many end users are unaware of how much home and office imaging devices rely on the consumables they employ. Often, these consumers purchase supplies solely on price and are disappointed when the performance of their machines deteriorates and the pages they print look lousy. In the end, they learn the hard way that the money they save by purchasing low-quality replacement cartridges costs them dearly in terms of the overall performance of their equipment and the print quality it delivers.

Whole Lot of R&D

The digital inks and toners—or “marking materials”—deployed in the latest home or office imaging devices represent decades of refinement and millions of research-and-development (R&D) dollars. To properly support a machine and allow it to achieve the appropriate print speeds, resolution, image permanence, and other characteristics associated with a particular device, marking materials must operate within the strictest tolerances. If there is any deviation from these tolerances, the machines may not operate properly and output may suffer.

Often, OEMs will design their printing platforms specifically for a certain ink or toner formulation and partner with a chemical manufacturer to produce the feedstocks and other raw materials for the marking materials. Many of the world’s most advanced chemical makers, such as BASF, DuPont, Kao, and Mitsubishi, produce the highly-engineered specialty chemicals used in the production of digital inks and toners for OEMs. Some chemical companies also make the actual finished ink and toner, too.

Most chemical companies do not work exclusively with OEMs. When reverse-engineering a cartridge, those third-party supplies vendors that strive to bring to market high-quality products also work closely with specialty-chemical manufacturers to develop marking materials that can meet the demands of a specific machine. Often, these third-party formulations are propriety to the non-OEM consumables maker. In some cases, certain OEMs will likewise develop third-party marking materials that compete with another hardware vendors consumables, especially toners, which have been sold in bulk by firms like Ricoh and Xerox for machines for other OEMs.

Highly Engineered

The proper operation of any printing machine depends largely on the marking materials it employs. Digital inks contain special chemicals such as humectants to prevent nozzles from drying out and surfactants to ensure that each of the millions of droplets that are fired per second has the right surface tension. The inks must also penetrate the substrate they hit without bleeding into each other as well as dry almost instantly to keep from smearing.

Toner powder is similarly complex. Each tiny particle, which is usually 10 microns or less in diameter, features a resin base that melts, spreads, and adheres to a substrate in a fraction of a second. The particle itself is treated to ensure its flow characteristics allow it to move within the toner cartridge, while its electrostatic properties are controlled to make sure it is placed with a high degree of accuracy before being fused to a substrate. Residual toner must also be easy to remove from the imaging drum after printing so the next page can be processed.

The look and feel of the output from any digital imaging device is also the direct result of the marking materials employed. Most inks used in digital printing devices for the home or office feature an aqueous liquid, or “vehicle,” to apply dye-based or pigmented colorants to a page. Dyes are made of molecules that can penetrate a substrate and dry almost immediately. While they tend to be quite vivid when initially applied, dye-based inks may fade over time due to the inherent unstable lightfastness of the chromophores in the chemicals that are used to make the inks. Pigments, on the other hand, are larger compounds that sit on the substrate’s surface. While they lack the “pop” that dyes can deliver, pigmented inks are more lightfast and are often more resilient over time.

Just as different types of inks yield output with different characteristics, toner type also plays a large role in document quality. OEMs and third-party toner manufacturers employ different production techniques to make toners for different applications. Some toners are made through chemical reactions that form uniform particles that feature a colorant on the outside and a resin core, while other toners are made using an extrusion process that produces toner ingots, which are ground down mechanically. Depending on the way a toner is produced, the output it delivers may have a flat, matte, or glossy finish and may feel as if it has a wax coating.

Remanufacturers and companies that manufacture new compatible consumables face a daunting challenge when they attempt to bring to market non-OEM cartridges. They must develop marking materials that are compatible with the operation of a machine as well as capable of delivering high print quality and image permanence. And they must do all this without violating the many patents that OEMs hold on their ink and toner designs.

As noted, many high-tech firms, including specialty chemical manufacturers and hardware manufacturers with production assets, market third-party marking materials for third-party supplies vendors. With their own substantial patent portfolios and lots of technical expertise, chemical companies and OEMs are capable of developing high-quality third-party marking materials that can go toe-to-toe with the original ink and toner formulations. Of course, developing third-party ink and toner sets that are non-infringing and do not degrade the performance of a digital imaging device is no small feat and takes plenty of R&D dollars. As a result, these high-performing, non-infringing marking materials sell for a premium and are not used in the cheap ink and toner cartridges.

What Are They Saying on Amazon?

Amazon has become a huge channel for OEM and third-party supplies, especially among consumers looking for supplies for inkjet and toner-based devices used in small offices and homes. We sampled reviews for some of the best-selling supplies on Amazon, which are among the most numerous. The reviews of these popular SKUs support the notion presented above that poor inks and toners hamper a printing device’s overall performance.

While high prices and low page yields were the most common lament we found among OEM-cartridge buyers on Amazon, consumers who purchased third-party cartridges had a much broader set of complaints. Gripes about poor image quality and poor color matching were common. Some reviewers complained that their third-party cartridges leaked, while others said their products failed after printing only a few pages or didn’t work at all. Third-party cartridge buyers were also often unhappy with the service they received when they attempted to contact the firms that sold them underperforming cartridges.

When we checked, the best-selling inkjet SKU on Amazon was a twin-pack of OEM HP 63 cartridges that contained one black ink cartridge and a tricolor cartridge. Based on 2,643 customer reviews, the SKU had a rating of four out of five stars, with 83 percent giving it three or more stars and 17 percent giving the twin-pack one or two stars. While a couple of customers gave bad ratings because they had ordered the wrong SKU or the packaging was damaged, most complained that the cartridges were expensive and had to be replaced often. We didn’t see any poor reviews related to image quality. One customer couldn’t get the OEM cartridges to work and gave them a low rating, but HP contacted the individual after reading the review, after which the rating was raised to five stars.

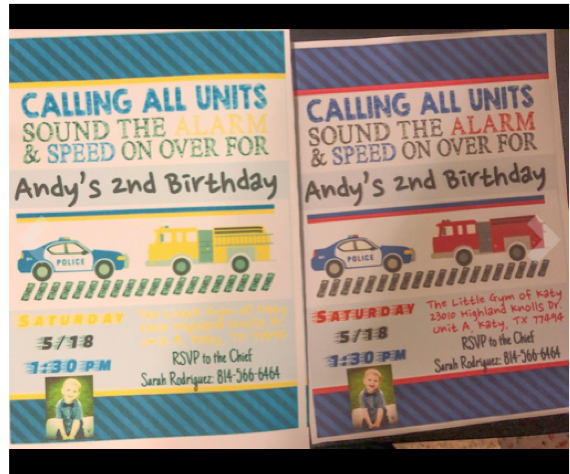

For our comparison, we couldn’t find a third-party HP 63 cartridge so we opted for the top-selling HP 63 XL third-party offering. The most popular SKU when we checked Amazon was a twin-pack (K+CMY) of Greenbox remanufactured cartridges, which was ranked 36th among the top 100 ink cartridge SKUs. Based on the 326 reviews submitted to Amazon, this product had a rating of 4.4 out of five stars, with 87 percent giving it three or more stars and 13 percent giving the twin-pack one or two stars. Many of the nearly 50 negative reviews were complaints that one or both of the cartridges failed to print or stopped printing after only delivering a few pages. Many also complained about the poor image quality and that pages smeared. One customer reported printing a boarding pass that was rejected at the airport because the bar code couldn’t be read by the scanner. Another common complaint was that the colors printed poorly or faded quickly, which is an indication that the cartridges contained low-quality inks. One customer sent in a picture, which we’ve included in this post, of an invitation printed with the Greenbox cartridges compared to one printed with the OEM product. The fading was presumably caused by very unstable dyes used in the Greenbox ink set.

The lowest-priced non-OEM twin-pack (K+CMY) of HP 63 XL cartridges was from MYTONER and sold for $27.88, which was about 7 percent less than the $29.99 Greenbox SKU and almost 40 percent lower than the $45.89 OEM SKU. The MYTONER product only had 24 reviews and received 3.7 stars, with 67 percent giving the twin-pack three or more stars and 33 percent giving it one or two stars. Many of the same issues were mentioned in the negative reviews for this SKU, including cartridges that failed to work and poor color matching and fading, but we also saw more reviewers complaining that these cartridges leaked. Remanufacturing ink cartridges requires good empties; otherwise, leaking may occur. The refilling process and the inks could also be to blame. If the proper backpressure in the cartridge is not maintained, ink can “drool” from nozzles. Several of the reviewers indicated that they received the wrong cartridges and that although the label said the box contained HP 63 XL remans, the cartridges didn’t fit their printers.

Toner Comparisons

The best-selling toner cartridge on Amazon when we checked the site was the Brother TN660 black OEM toner cartridge, which was listed for $53.97. It had an average rating of 4.4 stars from 2,321 reviewers, with 90 percent rating this SKU with three or more stars and 10 percent giving it a one- or two-star rating. Like the reviews we read for the OEM HP ink cartridges, the biggest complaint among the Brother TN660 reviewers was related to the cost of the cartridge and page yields. One reviewer gave the product three stars because of a printer setting that stopped the cartridge from being fully depleted and explained how to reset the printer so it would fully exhaust the toner cartridge. We also found several reviewers who were impressed by Brother’s service when they contacted the OEM after encountering problems replacing the spent cartridge.

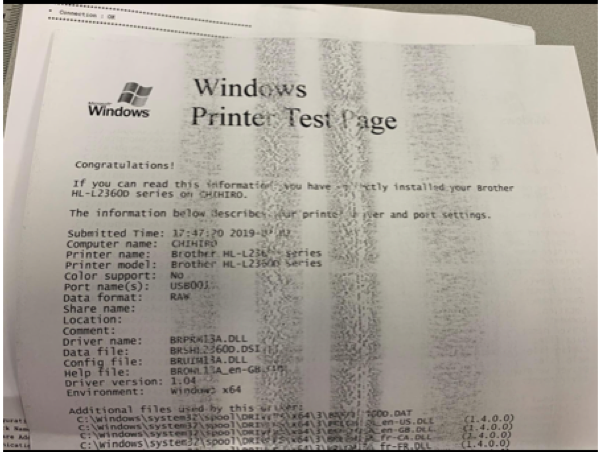

The most popular third-party Brother TN660 compatibles were from Linkyo. The company offered a twin-pack for $20.95, which was the seventh most popular toner SKU being sold on Amazon when we checked. Linkyo also offed a single TN660 for $12.95. Each compatible SKU had approximately 1,250 reviews, with the twin-pack getting an average of 4.3 stars and the single-cartridge SKU receiving a 4.4-star rating. The majority of complaints were about streaky output, which is often caused by using incompatible toners. Using toners with improper electrical characteristics can cause problems when the toner is transferred to the drum and to the page. Poorly matched toners can also be hard to remove from the imaging drum during the cleaning process, which can also result in poor print quality. A reviewer sent the picture below, indicating that toner was leaking from the cartridge. Another reviewer who purchased a twin-pack said one of the cartridges worked well but the second damaged the drum unit and printed poorly.

While many of the negative reviews that we’ve read about third-party supplies vendors mentioned poor or non-existent customer service, we did read that dissatisfied Linkyo customers were pleasantly surprised when they contacted the firm. One reviewer said the company was responsive and sent a replacement for a defective cartridge.

The Takeaway

We presented the Amazon reviews to offer some real-world examples of the critical role that toners and inks play in a printing device’s overall performance. While these examples are illustrative of the problems inks and toner can cause, they are by no means an exhaustive examination of the problem. Still, they show how inferior inks and toners can adversely impact a machine’s output as well as damage the device itself.

We should note that there were a number of inexpensive third-party consumables for machines from Canon, Dell, Epson, Lexmark, and others. We focused on just a handful of the top-selling SKUs because they would provide us with the most reviews. We saw many very low-cost ink and toner cartridges without a review or with only a few reviews, and we wonder how those SKUs perform.

In today’s imaging supplies market, consumers are faced with various value propositions that continue to expand due to the growing availability of inexpensive new-build and remanufactured products online. The Amazon reviews make it clear that the majority of bargain hunters are happy with the low price tags they find on so many third-party products; however, those buyers who were unhappy with the third-party products they purchased seemed to have some serious problems such as terrible-quality images being produced, if the product worked at all. So, we have to ask—are the savings really worth it?

1 Comment

I think the savings are worth it.